Open pools can be off-putting in the infamous British climate. But a Somerset couple make use of theirs every day of the year, thanks to the oak framed pool house.

Edward and Annette, the owners of a lovely dwelling in picturesque Somerset countryside built an oak framed swimming pool house to give themselves an opportunity for year-round low impact exercise, whilst enjoying the views of the beautiful valley near their house.

Project Basics:

Key Features:

Time line & budget:

Having previously built an oak framed garage on the grounds of their home, Edward and Annette could call themselves seasoned oak frame building patrons. So when they decided to build a swimming pool to enjoy an active life all year-round, an oak building to protect the pool from the elements was an obvious choice. They approached Oakmasters with a vision and a few sketches, hoping they will get just what they had in mind.

The couple, both with engineering backgrounds decided to embark on the planning process themselves. Armed with some initial sketches from Oakmasters and a location plan provided by a local architectural firm, they applied for planning permission with their local authority. Features such as solar panels really helped with the application process, which took 10 weeks from start to finish and Edward and Annette finally got the planning permission through in July 2016.

The couple spent some time researching the oak frame manufacturing companies prior to applying for planning consent. Finally, they settled on Oakmasters, as they were impressed with the oak framed pool house projects we previously completed.

Edward and Annette asked Oakmasters to produce complete architectural designs for the pool building, with four main criteria in mind:

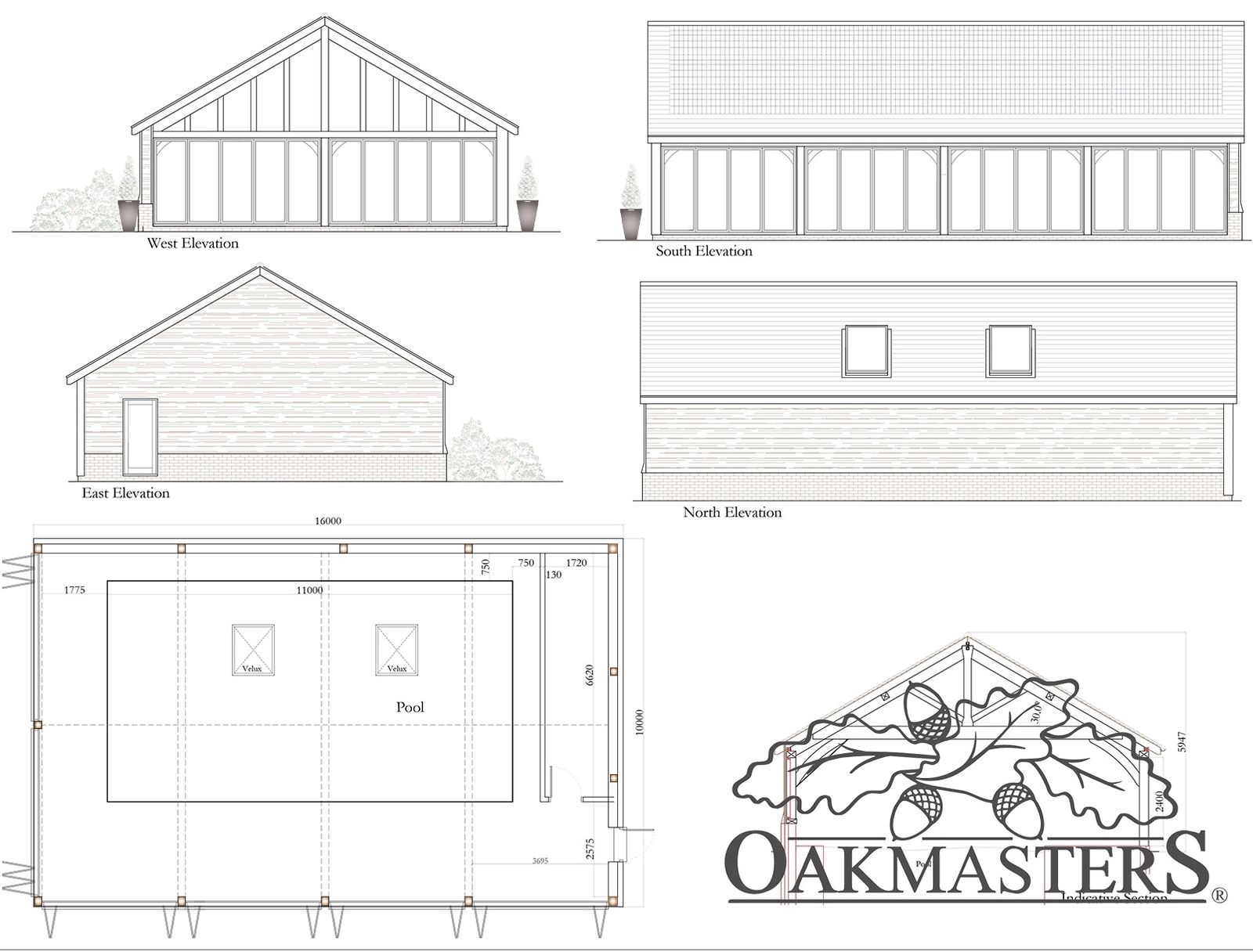

Visually, the building looks like a traditional barn from the East and North elevations and features large glazed walls as well as solar panels on the South and West elevations. A utility area at the rear contains a shower room and plant room, essential for the functioning of the pool and for comfort. A small door at the rear leads towards the main house.

After a site visit and an initial draft from Oakmasters, the project got underway, with structural calculations and subsequent details and production designs to follow. Once these were all approved, the couple were happy to proceed with the project.

The oak frame went into production in Oakmasters factory in late April 2017. Meanwhile, groundworks were underway on site, getting the space ready for the frame. When the frame arrived on site in August 2017, Oakmasters assembly subcontractors undertook the management of the project and got busy erecting the frame.

First, the sole plates around the perimeter of the building, then posts and top plates. Finally, pre-constructed oak trusses were craned in to complete the structure. Once the main oak frame was complete, the building contractors finished the roof and the solid wall build up, including oak featheredge cladding on the North and East elevations. Shortly after, bifold doors and encapsulated glazing system made the building water tight and ready for the finishing touches such as exterior capping, interior rendering and other details.

As with all construction projects, there were a few challenges along the way, such as electricity outages, which hindered crane operation, various minor delays, which lead to rescheduling and re-arranging of various processes, but everything was resolved smoothly by good communication.

The couple finally started using the pool in January 2018.

“We took a risk not using an architect or project manager, but it paid off.”, says Edward. “We contracted the building team and others directly and it worked out fine. Oakmasters’ quality craftsmanship and their installation team were great in supporting us all the way.

We really enjoy our pool now. It’s stunning to look at and to be in, and we use it every day, as planned.”

See all pictures of this project.

Oakmasters design, manufacture and assemble bespoke oak and glulam timber frame structures. For more images of this project, see our website gallery. For a no obligation chat or a quotation, please call us on 01444455455 or email [email protected]

We'd love to hear about your oak framed project. Call us today on +44 (0) 1444 455 455 +44 (0) 1444 455 455 for a no obligation estimate. Alternatively, complete the form below and we will be in touch.